Centrifugal Pumps Viscosity Range . depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary. Depending on the pump type, the impact of liquid viscosity is different. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown in equation 1. A dimensionless number called b helps predict the viscous component of each correction factor. We will look at three types of. centrifugal pumps are best suited for liquids that have a viscosity range between 0.1 and 200 cp. generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400.

from www.rotechpumps.com

centrifugal pumps are best suited for liquids that have a viscosity range between 0.1 and 200 cp. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes. Depending on the pump type, the impact of liquid viscosity is different. We will look at three types of. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown in equation 1. A dimensionless number called b helps predict the viscous component of each correction factor. generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400. depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary.

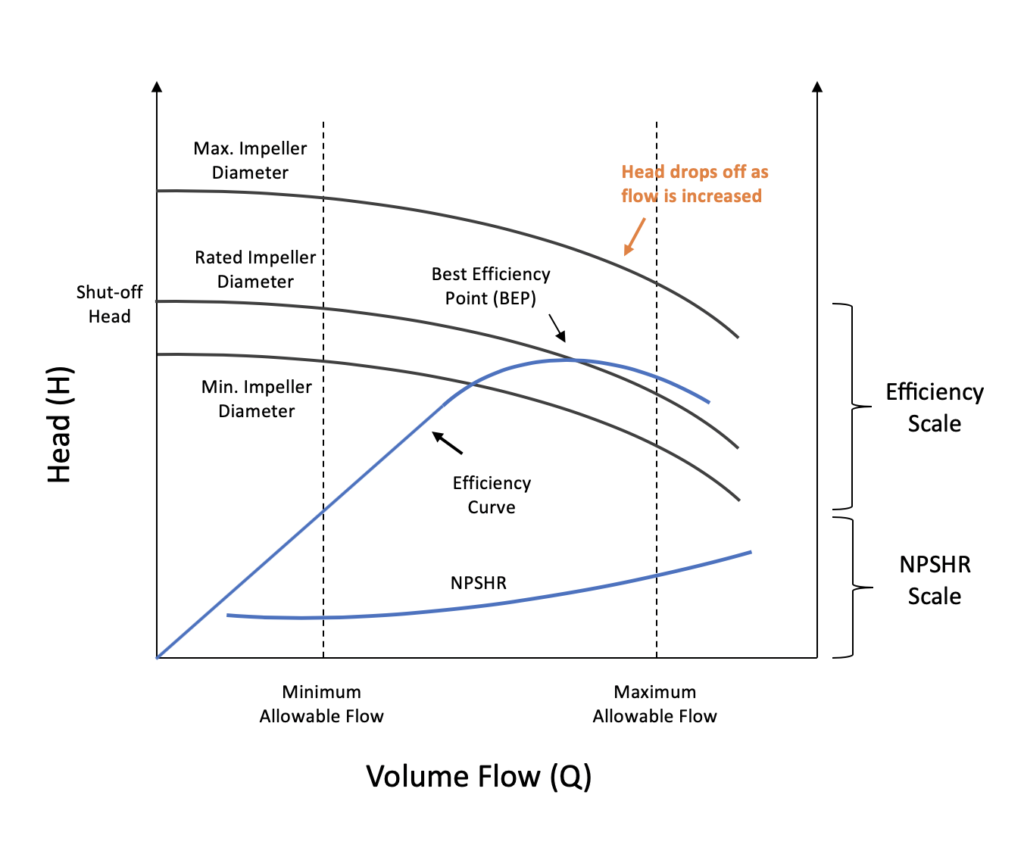

Understanding Pump Curves for Centrifugal Pumps A Comprehensive Guide

Centrifugal Pumps Viscosity Range We will look at three types of. centrifugal pumps are best suited for liquids that have a viscosity range between 0.1 and 200 cp. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown in equation 1. depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes. We will look at three types of. generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400. Depending on the pump type, the impact of liquid viscosity is different. A dimensionless number called b helps predict the viscous component of each correction factor.

From www.youtube.com

Types of Centrifugal Pumps 8 different types of Centrifugal Pump Centrifugal Pumps Viscosity Range Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes. Depending on the pump type, the impact of liquid viscosity is different. A dimensionless number called b helps predict the viscous component of each correction factor. generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400. centrifugal pumps are best suited for. Centrifugal Pumps Viscosity Range.

From exomjxste.blob.core.windows.net

Viscosity For Centrifugal Pump at Ortega blog Centrifugal Pumps Viscosity Range generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown in equation 1. . Centrifugal Pumps Viscosity Range.

From chempedia.info

Viscosity correction, centrifugal pumps Chart Big Chemical Encyclopedia Centrifugal Pumps Viscosity Range We will look at three types of. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown in equation 1. A dimensionless number called b helps predict the viscous component. Centrifugal Pumps Viscosity Range.

From labbyag.es

How To Read A Pump Curve Chart Labb by AG Centrifugal Pumps Viscosity Range A dimensionless number called b helps predict the viscous component of each correction factor. depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes. Depending on the pump type, the impact of liquid viscosity is different. We will look at. Centrifugal Pumps Viscosity Range.

From deltatsys.com

Positive Displacement Pump vs. Centrifugal Pump Centrifugal Pumps Viscosity Range A dimensionless number called b helps predict the viscous component of each correction factor. We will look at three types of. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown in equation 1. generally speaking, centrifugal pumps are extremely. Centrifugal Pumps Viscosity Range.

From www.scribd.com

Fluid Viscosity Effects in Centrifugal Pump Centrifugal Pumps Viscosity Range centrifugal pumps are best suited for liquids that have a viscosity range between 0.1 and 200 cp. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown in equation 1. depending on the pump size and impeller geometry, the. Centrifugal Pumps Viscosity Range.

From www.kehuanpumps.com

How to Make Viscosity Corrections for Centrifugal Pumps Centrifugal Pumps Viscosity Range generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400. depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow. Centrifugal Pumps Viscosity Range.

From www.industrialchemicalpump.com

High Pressure High Viscosity Horizontal Chemical Pumps, Chemical Centrifugal Pumps Viscosity Range generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400. We will look at three types of. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown in equation 1. centrifugal pumps are best. Centrifugal Pumps Viscosity Range.

From www.pumps.org

How Viscosity Affects Pumping Centrifugal Pumps Viscosity Range generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400. We will look at three types of. A dimensionless number called b helps predict the viscous component of each correction factor. Depending on the pump type, the impact of liquid viscosity is different. depending on the pump size and impeller geometry, the viscosity. Centrifugal Pumps Viscosity Range.

From chempedia.info

Viscosity correction, centrifugal pumps Chart Big Chemical Encyclopedia Centrifugal Pumps Viscosity Range generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes. A dimensionless number called b helps predict the viscous component of each correction factor. Depending on the pump type, the impact of liquid viscosity is different. depending on the pump size and. Centrifugal Pumps Viscosity Range.

From www.csidesigns.com

How to Read a Pump Curve Pump Characteristic & Performance Curves Centrifugal Pumps Viscosity Range A dimensionless number called b helps predict the viscous component of each correction factor. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown in equation 1. generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity. Centrifugal Pumps Viscosity Range.

From theconstructor.org

Centrifugal Pump Components, Working, Types and Application Centrifugal Pumps Viscosity Range depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown in. Centrifugal Pumps Viscosity Range.

From www.anchorpumps.com

Positive Displacement Pumps vs. Centrifugal Pumps The Complete Guide Centrifugal Pumps Viscosity Range Depending on the pump type, the impact of liquid viscosity is different. generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400. depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary. to account for the effects that a viscous fluid has on pump. Centrifugal Pumps Viscosity Range.

From exomjxste.blob.core.windows.net

Viscosity For Centrifugal Pump at Ortega blog Centrifugal Pumps Viscosity Range generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400. Depending on the pump type, the impact of liquid viscosity is different. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown in equation 1.. Centrifugal Pumps Viscosity Range.

From www.pumpsandsystems.com

Reciprocating Pumps vs. MultiStage Centrifugal Pumps Pumps & Systems Centrifugal Pumps Viscosity Range We will look at three types of. Gravity viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes. generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400. Depending on the pump type, the impact of liquid viscosity is different. A dimensionless number called b helps predict the viscous component of each correction factor.. Centrifugal Pumps Viscosity Range.

From www.researchgate.net

Operating range of centrifugal pump with VSD (a) evolution of Head and Centrifugal Pumps Viscosity Range depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary. We will look at three types of. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown in equation 1. generally. Centrifugal Pumps Viscosity Range.

From www.northridgepumps.com

How to Read a Pump Curve Centrifugal Pumps Viscosity Range depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary. Depending on the pump type, the impact of liquid viscosity is different. to account for the effects that a viscous fluid has on pump performance, an engineer can use general correction factors for head, volumetric flow rate and efficiency, shown. Centrifugal Pumps Viscosity Range.

From www.ogj.com

Equations correct centrifugal pump curves for viscosity Oil & Gas Journal Centrifugal Pumps Viscosity Range We will look at three types of. centrifugal pumps are best suited for liquids that have a viscosity range between 0.1 and 200 cp. generally speaking, centrifugal pumps are extremely inefficient conveyors of liquids when fluid viscosity exceeds 1,400. depending on the pump size and impeller geometry, the viscosity limits for the average centrifugal pump will vary.. Centrifugal Pumps Viscosity Range.